Thinsulate Machines Seal and Cut

1、Working video

https://www.youtube.com/watch?v=OfSmFxwLHzg

2、Application

This machine is suitable for automatic hot press forming and punching production of rolled materials, and continuous automatic punching operation for a series of non-metallic materials such as soundproof cotton and thinsulate.

The machine adopts automatic feeding of the rolled material and automatic hot pressing, and the formed material is manually taken out from the discharging platform.

3、Main technical specifications

Ø Max cutting force: 2000KN;

Ø Heating platen area: 1600x1000mm;

Ø Tension distance: 20-170mm;

Ø Stroke adjustment range: 5-150㎜(adjustable);

Ø Applicable material width: ≤1600㎜;

4、Structural composition

The machine consists of a discharging part, a conveying and feeding part, a synchronous discharging part, a punching main part, a pneumatic system, an electric control system, a safety protection system, and so on.

5、Operation steps

Set relevant parameters on the touch screen of the electric control cabinet, Fix the die cutter in the punch head,The worker pull the material under the feeding air clip, clamp air clip, the machine feeding the material automatic, press the start button, the platen goes down, after punch the platen rises again, feeds again, punches again, and the synchronous discharge part outputs the punched product together with the scraps, and manually picks up the finished product. Press the start button again, the machine automatically feeds, automatically punches, and so on.

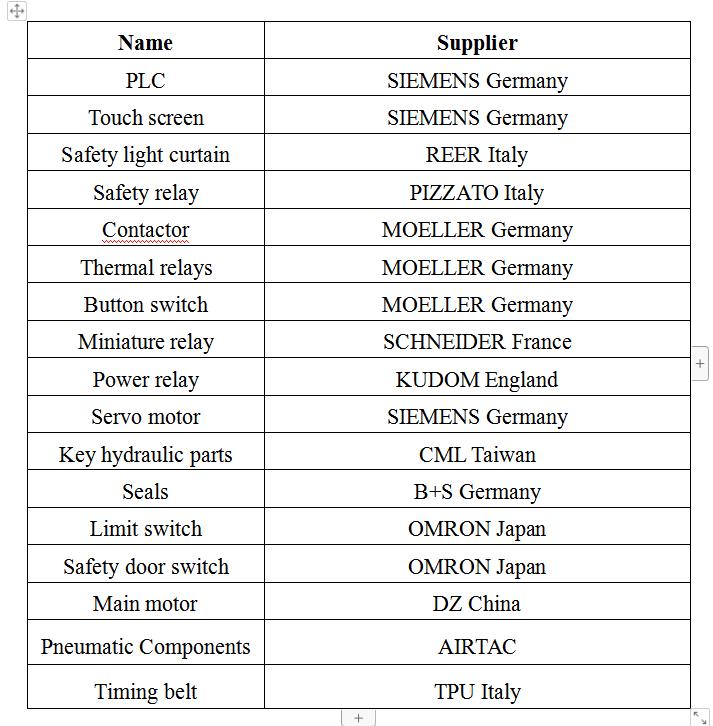

6、The main component suppliers